The CHM-Z series energy-saving self-priming inverter water pump - equipped constant pressure pump offers adjustable pressure, energy - saving with high flow rate, multi - function, self - priming, anti - freezing, low - noise, multi - protection, and operates with a wider voltage range.

Available Output :

0.5HP/ 0.75HP /1.0HPVoltage/Hz :

110V / 220V ; 50/60HzControl Box :

Button type ;Touch Screen LCD type with WIFICustomized Service :

Brand/ Logo/ User manual/ Unit BoxMOQ Order :

50 PCSWarranty :

12 MonthsEnergy Saving Self-priming Inverter Water Pump CHM-Z Series

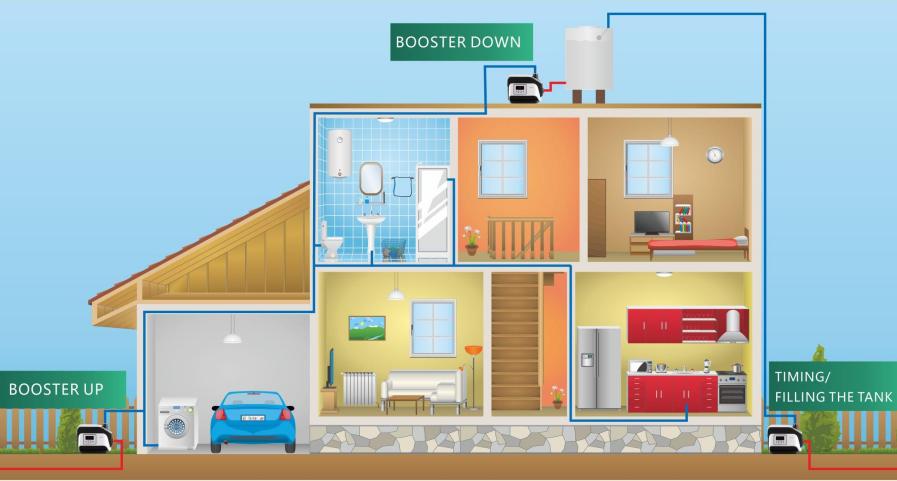

The CHM-Z pump features a plug-and-play design, making installation simple and efficient even for first-time users. The variable frequency pump with Self-priming function and could be working for the household water supply, water supply system, cooling system, booster system etc. The wide voltage design from 130V to 280v Ac for different market request.

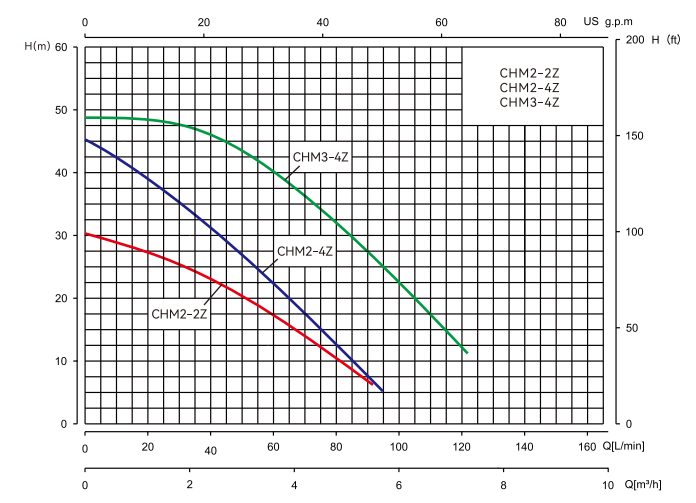

Technical Data

|

Model |

Voltage |

Power |

Current |

Speed |

Flow (m3/h) |

Head(M) |

Suction |

Inlet/Outlet |

||

|

V/ HZ |

HP |

KW |

A |

RPM |

Rated |

Max. |

Rated |

M |

||

|

CHM2-2Z |

220V; 50/60HZ |

0.5 |

0.37 |

2.5 |

4500 |

1.5 |

30 |

25 |

3 |

1"x1" |

|

CHM2-4Z |

220V; 50/60HZ |

0.75 |

0.55 |

3.5 |

4000 |

2 |

45 |

35 |

6 |

1"x1" |

|

CHM3-4Z |

220V; 50/60HZ |

1 |

0.75 |

6.2 |

4000 |

3 |

48 |

40 |

6 |

1"x1" |

Note: the standard controller is button type, option by LCD touch screen type with WiFi functioin; please metion in the inquiry before your order

Product Features

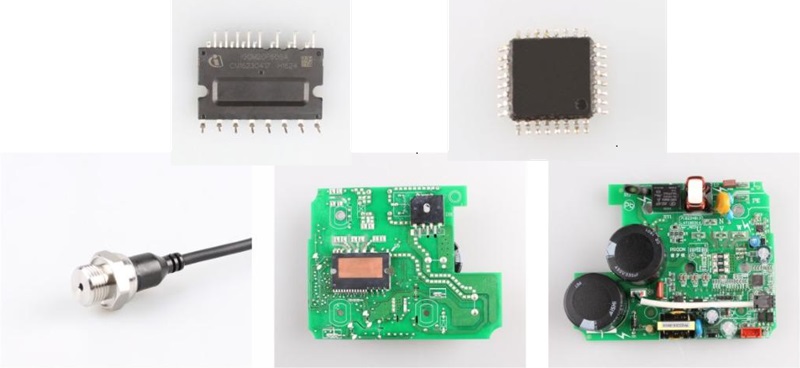

AISI304 welding shaft Permanent magnet motor

Motor with copper winding Builtin thermal protector for single phase motor

Working codition:

Max. liquid temperature:+ 60℃ Altitude: up to 1000 m

Max. inlet pressure: 10bar Max. operation pressure: 10 bar

Liquid PH Value: 6.5 -8.5 Insulation class: B

Protection class: IPX4 Max. ambient temperature: +40℃

Thanks to its self-priming capability, the pump can automatically evacuate air from the system and draw water into the impeller chamber without manual priming. This feature simplifies installation and startup, especially in environments where initial water levels are unstable or when dry-run protection is needed.

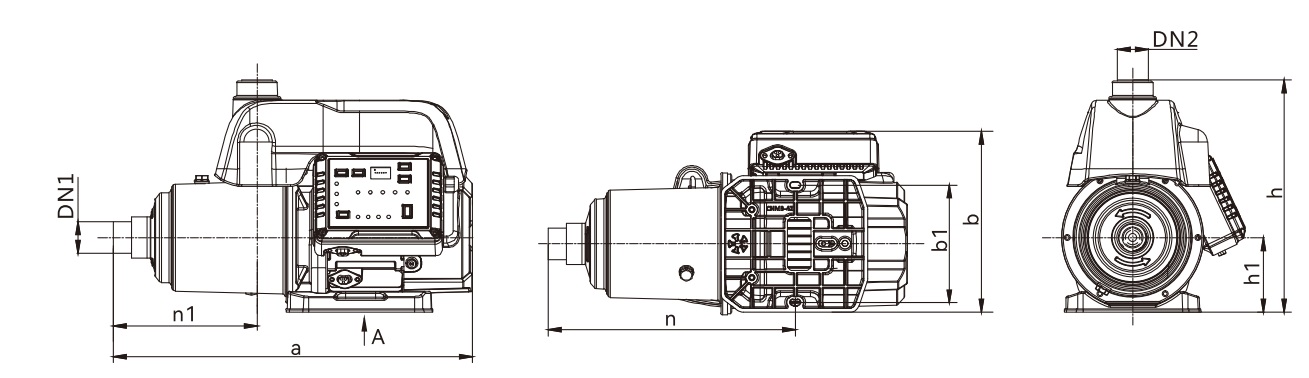

Installation Dimensions

| Model | DN1 | DN2 | a (mm) | b (mm) | b1 (mm) | h (mm) | h1 (mm) | n (mm) | n1 (mm) | Carton Size (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| CHM2-2Z | G1 | G1 | 368 | 212 | 138 | 273 | 88 | 237 | 116 | 419 × 260 × 325 |

| CHM2-4Z | G1 | G1 | 421 | 212 | 138 | 273 | 88 | 290 | 169 | 472 × 260 × 325 |

| CHM3-4Z | G1 | G1 | 421 | 212 | 138 | 273 | 88 | 290 | 169 | 472 × 260 × 325 |

WHY CHOOSE OUR PUMPS?

Our Certificates

Frequently Asked Questions

Q1: Is the CHM-Z pump easy to install?

A1: Yes, the pump is designed with a plug-and-play structure. It comes pre-wired and factory-configured, requiring only standard pipe and power connections. No special tools are needed.

Q2: What kind of liquids can this pump handle?

A2: The CHM-Z pump is suitable for clean water and light industrial liquids that are non-corrosive and free of solid particles. For slightly contaminated water, a pre-filter is recommended.

Q3: Can I control the pump remotely?

A3: Yes, the pump supports smartphone APP control. You can remotely start/stop the pump, adjust pressure, switch working modes, and monitor system status in real time.

Q4: What are the available working modes?

A4: There are three modes: Booster Up, Booster Down, and Timing/Filling the Tank. You can select and set the desired mode easily via the control panel or the mobile app.

Q5: How often does the pump need maintenance?

A5: The pump requires minimal maintenance. Under normal conditions, we recommend checking the impeller, seals, and electrical connections every 6 to 12 months.

Q6: What happens if the pump runs dry or the voltage fluctuates?

A6: The built-in VFD controller includes dry-run protection, overload protection, and voltage fluctuation safeguards to prevent damage and ensure safe operation.